Power Distribution Transformers form an inseparable part of the power supply system without which we cannot manage the supply and distribution of power to the end-users. While this device can have multiple applications, its main purpose is to regulate the power voltage that ensures the safety and efficiency of the entire power system. They are used at homes, commercial complexes, and various industries to manage the entire power grid. Power distribution transformers are used to step up or step-down voltage levels based on the user’s voltage capacity. It uses the working principle of Faraday’s law of induction. Another purpose of this device is to isolate electrical energy from one winding to another. There are various types of transformers used in electrical systems which mainly depend on the supply voltage. The most common types of transformers are:

- Power Transformer

- Distribution Transformer

- Dry-Type Transformer

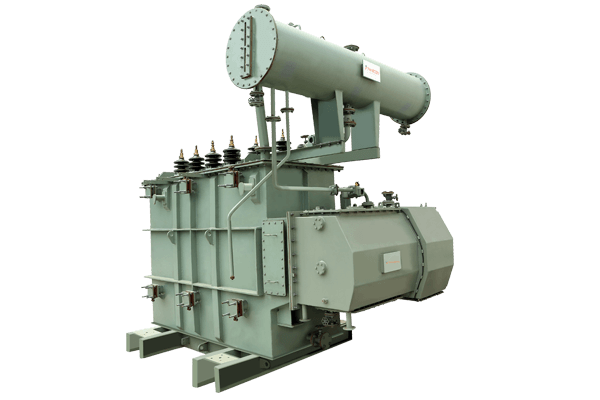

- Oil-Immersed Transformer

- Isolation Transformer

In addition to performing the task of managing the voltage levels of the power system, these devices have added features and capabilities that are used to address the very specific requirements of the project. For example, a power transformer is used to transmit power at a high voltage larger than 33kv at 100% efficiency. It is bigger and is used in producing stations and transmission stations with a high insulation rating. A distribution transformer is used to distribute power at a lower voltage less than 440v-220v for domestic purposes and 33kv for industrial applications. It can operate at low efficiency of 50-70%, is smaller in size, has low magnetic waste, and is not often fully loaded.

Regardless of the features and capabilities, most transformers also share many common features:

- The input and output frequency are the same

- The law of magnetic induction applies to all transformers.

- The primary and secondary coils of a transformer do not touch.

- Power is transferred through the magnetic flux.

- They do not use any internal moving parts.

To be fair, transformers can be built with virtually infinite permutations and combinations and there is no single way to identify what might work best unless you apply its working principles and conduct enough R&D to find what works best for a particular case. Of course, there are certain SOPs we can always adhere to. However, that only defines possibilities within a limited scope.

At Transcon Industries, we strive not only to meet prevailing standards of the industry but also to outdo them through consistency and rigorous R&D initiatives. Established in 2003, we have taken great strides in the field and have been delivering performance-driven transformers to our customers ever since. With our ISO 9001:2008, ISO 9001:2015, and ISO 14001:2015 certification, our stand as a company adhering to the highest levels of diligence and quality is cemented. Our products are also rated 5-star by the Bureau of Energy Efficiency. In addition to having established our name in the business with a long list of happy clients to vouch for us, we work tirelessly towards bettering our offerings through constant checks and optimizations from time to time. Our R&D team not only works to maintain our current systems and processes but also finds means to improve them gradually over time. While we strongly believe in taking a quantum leap in the field, we also put our faith in building our competencies from the ground up.

© 2020. Transcon Industries. Powered by  | Digital Marketing Services.

| Digital Marketing Services.